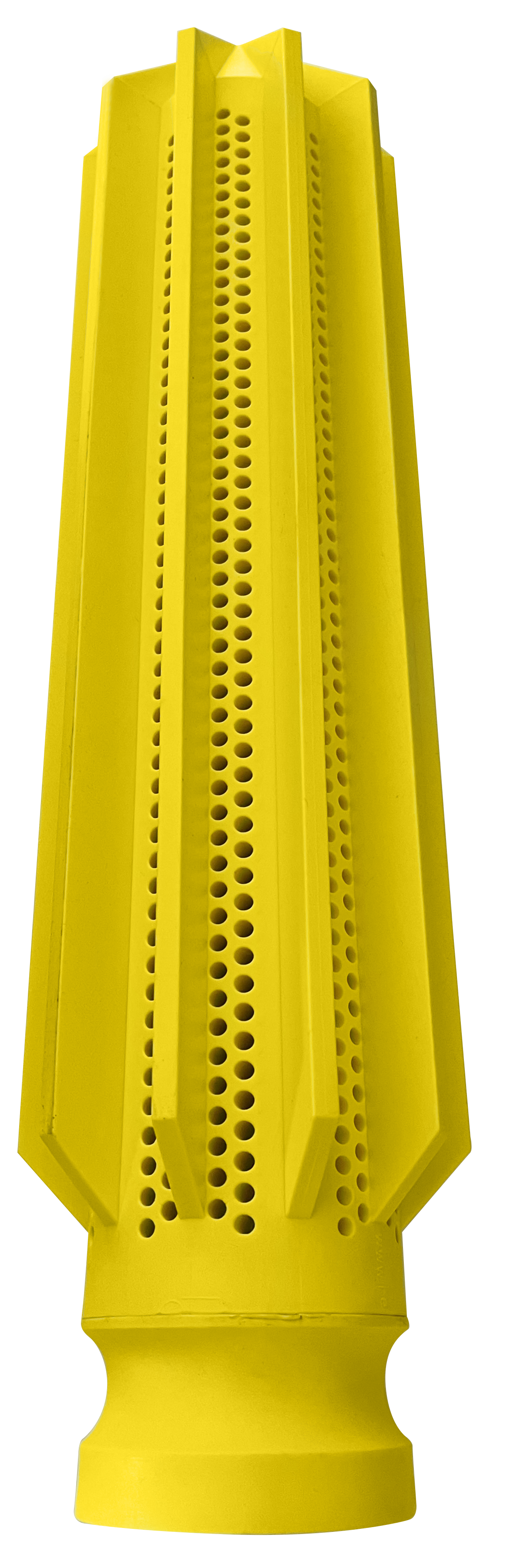

The Original. The First Reflex Suction Strainer with 3mm Filter Holes.

Advanced Flexible De-watering and Filtration Devices for Harsh Environments

Patent Pending no. 2015902356 - Australian Design Registration Number 362894 - United States of America Design Application Number 29/549,353 - International (PCT) Patent Application Number PCT/AU2016/050160

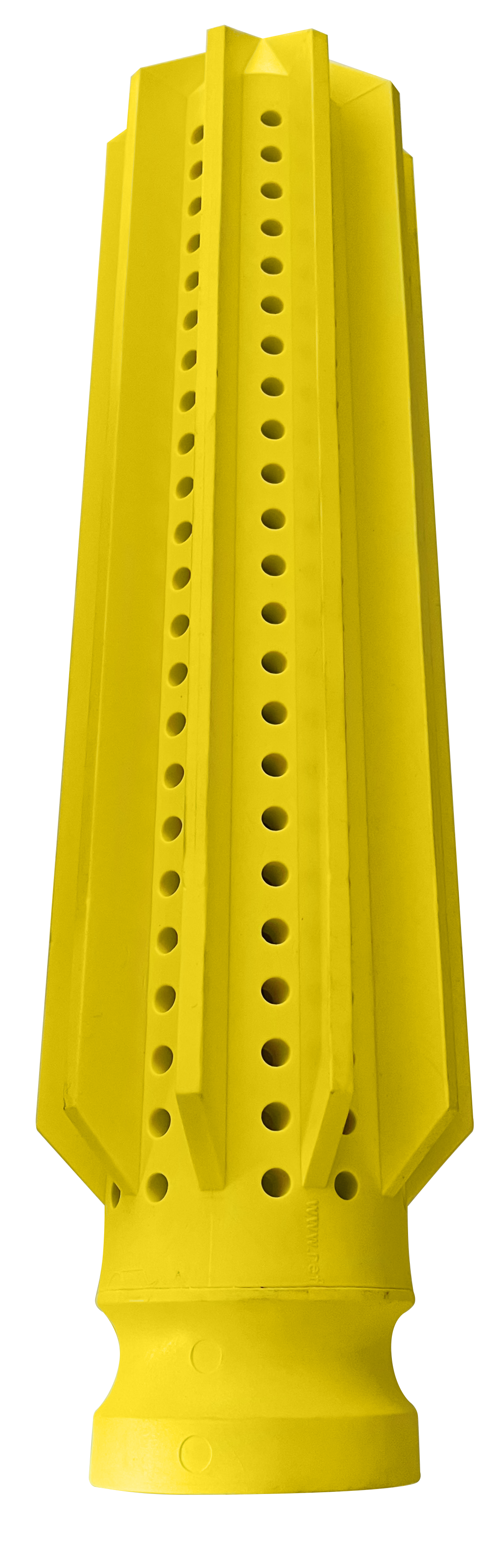

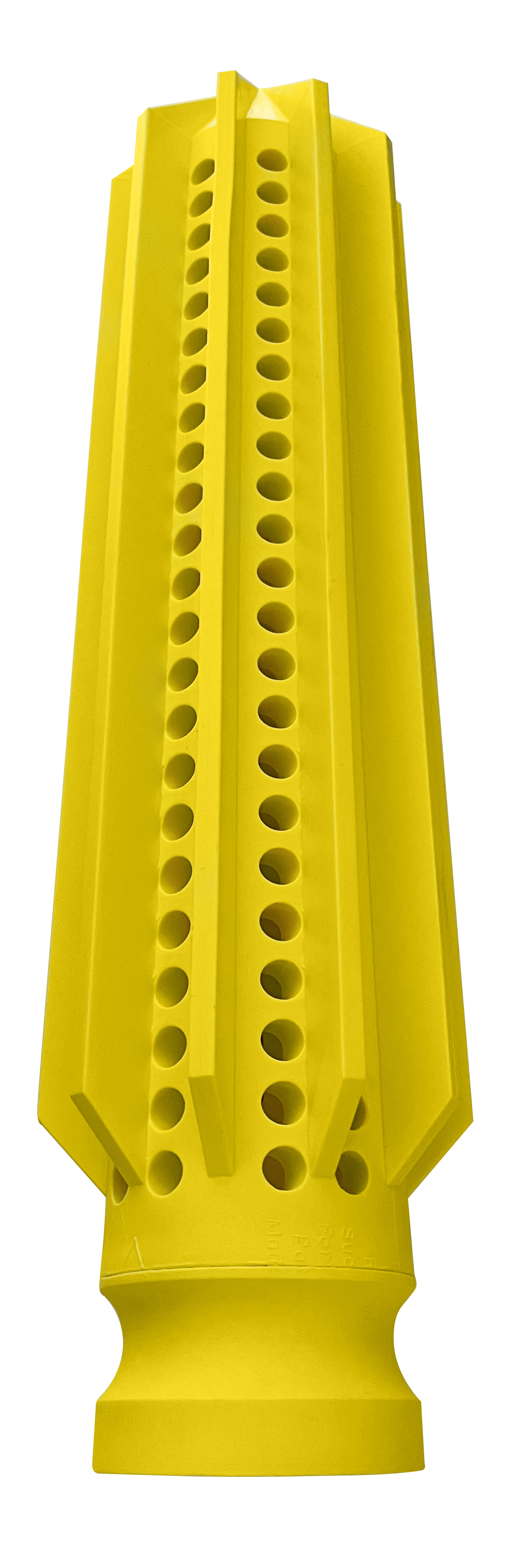

Born out of the high demands of the Australian underground mining environment, the Reflex Suction Strainer is designed to survive in hostile and high traffic environments. Moulded from an advanced blend of polymer rubbers, the Reflex Suction Strainer can handle extreme conditions including being run over by vehicles and machinery. The Reflex Suction Strainer costs less than conventional strainers, saving time in cleaning and replacements. Reflex Suction Strainers are safe to use and manufactured in accordance to ISO:9001 .

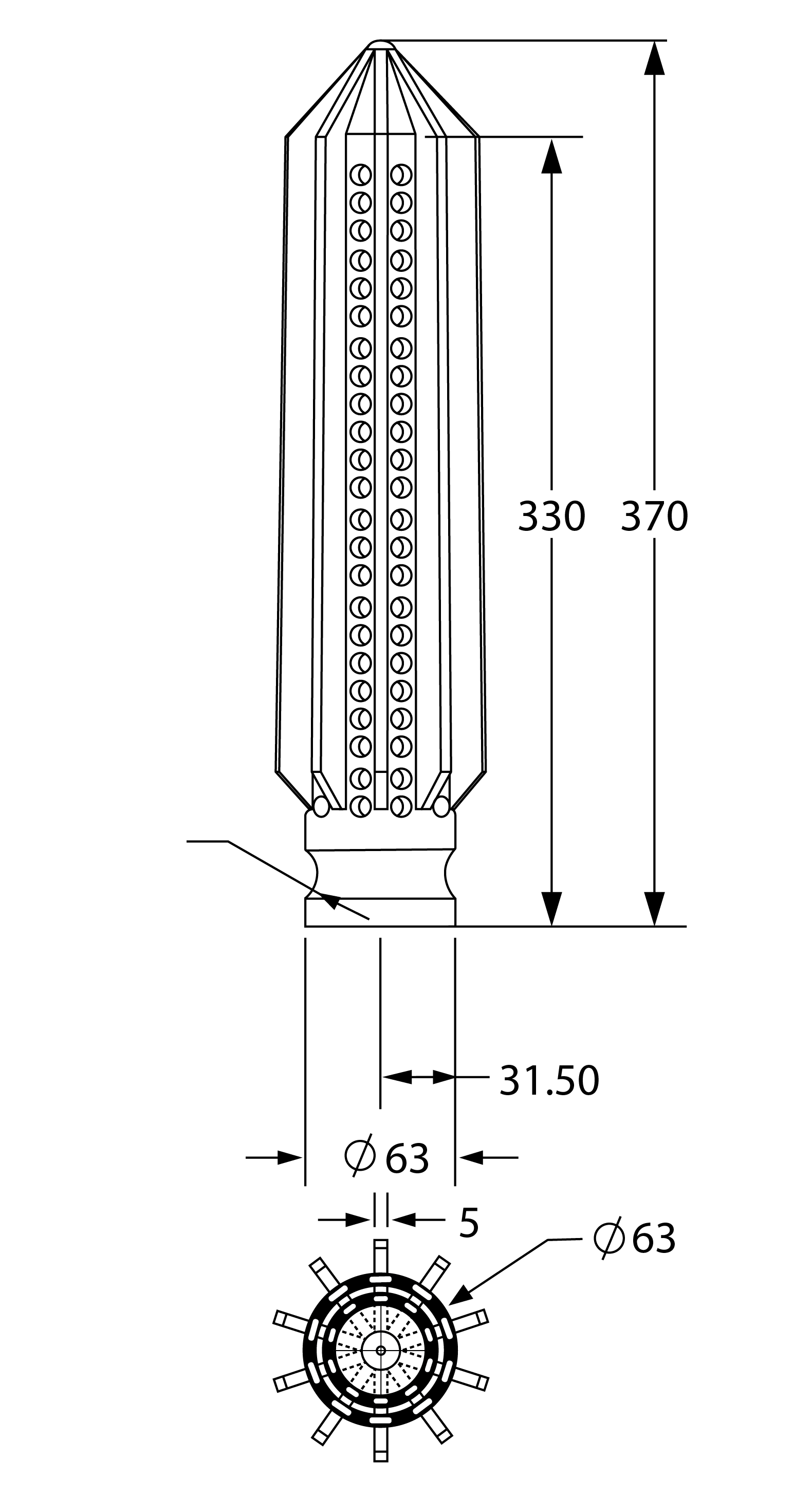

Specifications

Flow rate >850 litres per minute

Filtration flow 9 x surface area to suction aperture

Elongation Safe capability 450%

Length 370mm

Width 63mm

Weight approx. 550g

Hardness >60 - 70 shore A

Temp. range Safe -66°c to 100+°c

Colour Yellow (any colour on request minimum orders apply)

Size 2”

Hole Size 3mm

Manufactured in accordance to ISO9001

Benefits

Cost Savings

Does not corrode, therefore reduced replacement required

Sustains many heavy contacts without breaking allowing the part to last longer

Longer-lasting parts protect the pumps for longer periods, leading to less downtime, personnel intervention and repair and maintenance

No need to drill costly bore holes and associated equipment in development roadways as the product can be used directly on roads and in direct contact with machinery

More cost-effective pumps can be used keeping operating and capital costs down (diaphragm v submersible)

Applications

Underground and open cut development areas affected by excess water

Roadways subject to constant inundation with water

Any mining areas with high levels of water affecting production

The mining hose with flexible strainer is simply laid on the ground in the water affected zone and pumping may commence

No steel parts, bore holes or infrastructure needed from suction area to pump

Safety

The product uses vulcanised polymers eliminating sharp edges and reducing hand injuries (no metal) inherent in normal metal strainers

Removal of submersible steel objects and sharp objects, reducing trip and cut hazards

Lightweight and flexible design, meaning less impact on personnel and machinery when in contact

Quick and easy to clean, so personnel will spend less time in heavy traffic areas repairing or replacing equipment